- Overhead assembly

- 7-axles manipulators

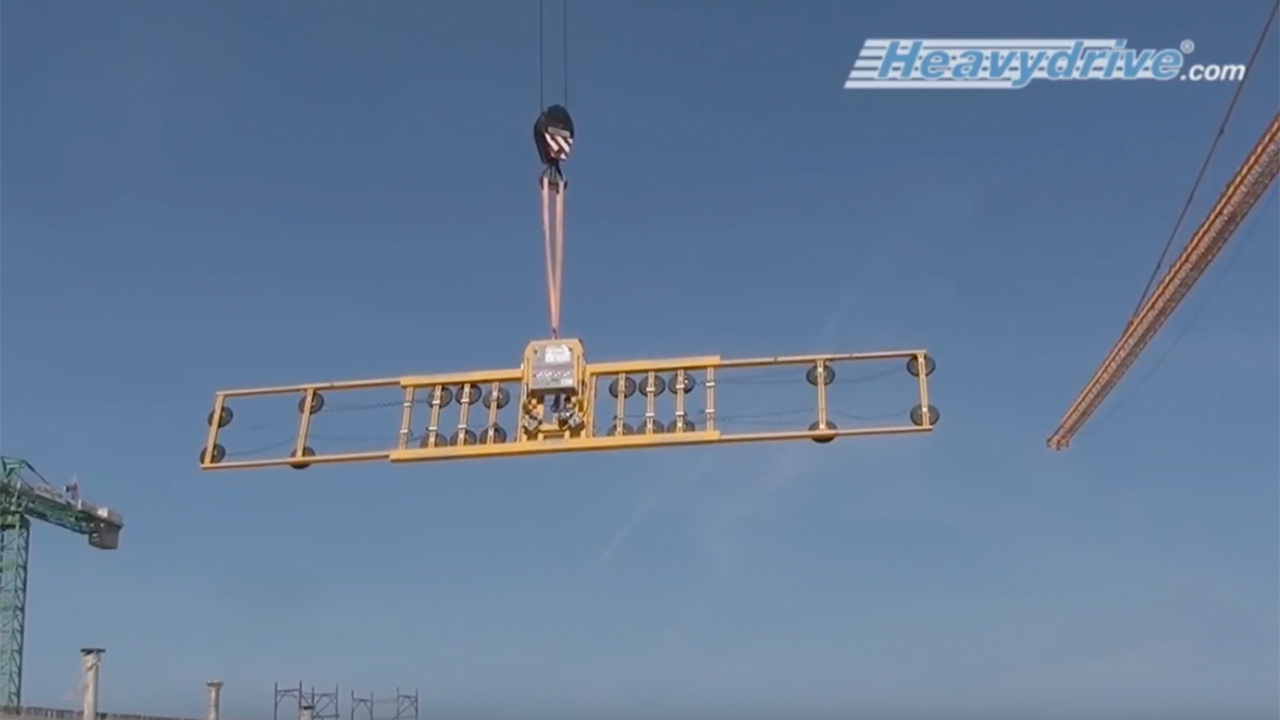

- VSGSTU 2000 K 7-axles-manipulator up to 2000 kg capacity

VSGSTU 2000 K 7-axles-manipulator up to 2000 kg capacity

| Features: | |

|---|---|

| Capacity: | 2000 kg |

| Net Weight: | 1000 kg |

| Pane vertical dimensions max.: | 5660 x 3530 mm |

| Pane horizontal dimensions max.: | 4660 x 2530 mm |

| Suction (L x W) (base frame): | 2150 x 1200 mm |

| Suction Cups: | 20 x T15 |

|---|---|

| Suction (LxW) with extension arms: | 3660 x 1530 mm |

| Safety System: | 4 circuit vacuum system |

| Battery: | 12 V, 3-4 days of continuous use without charging; recharging via 110/220 V plug |

7-axle-manipulator including remote control for assembling on a indoor or terrain telescopic forklift.

- Suction area (LxW) in mm (base frame) 2,150 x 1,200

- Suction area (LxW) in mm with attachment arms 3,660 x 1,530

max. pane dimension for wall glazing: 5660 x 3530 mm

max. pane dimension for roof glazing: 4660 x 2530 mm

forklift mounting: capacity 500 kg, 8 plates, weight of 300 kg, 7-axle-manipulator, 360°rotatable motorised, hydraulic tippable 90°, hydraulic tilting 40 degrees, 250 mm sideways movable, 250 mm front-back driving, hydraulic rotatable 40°, 12V-230V including wired remote control

The manipulator can be easily assembled by inserting the rented forklift into the forklift pockets at the foot of the equipment. The corresponding suction system on the manipulator is determined by our engineers beforehand. The axles can be moved by a person with remote control. Heavydrive sells this equipment on the German and on international markets, e. g. for a project in New York/USA. 15 m long and 1 m wide sheet metal panels weighing 800 kg are positioned transversely under a protrusion using the telescopic forklift here. In doing so, it is important to ensure a tongue and groove joint, which is only possible with a 7-axle-manipulator.

- 1st Axis: VSG suction system motorised full 360° turning

- 2nd Axis: VSG suction system hydraulic pivoting 0-100°, 0° horizontal to 90° vertical with an extra 10°

- 3rd Axis: Hydraulic sideways tilting 20° to the left / 20° to the right to compensate for the lateral tilt of the telescopic forklift

- 4th Axis: Side-shift hydraulic movement left / right 250 mm

- 5th Axis: Hydraulic forward / backward movement of the suction manipulator 250mm

- 6th Axis: Hydraulic raising / lowering of the manipulator by 250 mm

- 7th Axis Manipulator rotating tower 90° to the left or 90° to the right for lateral transport, e.g. through gates or side glazing

- Connection to telescopic lift truck manual: Forklift pockets on the side of the device, mechanically secured by screws

- Connection to telescopic lift truck automatic: Placement into fork lifter hook, hydraulically screwed

- Transport dimensions in mm: L 2,050 x W 1,200 x H 1,600 with suction frame, basic unit H 1,000

- Deepest over-head suction size: unbeatable 1,130 mm above ground

Rental/purchase prices: on request

- Glass construction

- Facade construction

- Window glazing

| Estimated delivery time when purchased as new: | 8 weeks |

|---|---|

| plus freight, packaging and shipping costs: | On request |

| Transport: | on a pallet |

» News & Jobs

All categories and product areas

VSGSTU 2000 K 7-axles-manipulator up to 2000 kg capacity

✓

successfully added to the inquiry list

Matching: